In 3D Printing, Vietnam’s Biomedical and Material Frontiers

Published on December 25, 2025 by Admin

In today’s rapidly evolving technological landscape, 3D printing, also known as additive manufacturing, is emerging as a transformative force. This technology offers unparalleled potential, especially within Vietnam’s burgeoning biomedical sector and its advanced materials industry. Researchers, material scientists, and manufacturers in Vietnam are increasingly exploring its capabilities. Therefore, understanding the nuances of 3D printing is crucial for harnessing its full benefits.

This article delves into the significant opportunities that 3D printing presents for Vietnam. We will explore its applications in biomedicine and advanced materials. Furthermore, we will discuss the underlying technologies and the unique advantages they offer. Finally, we will consider the future prospects and challenges for its adoption.

The Foundation: Understanding 3D Printing

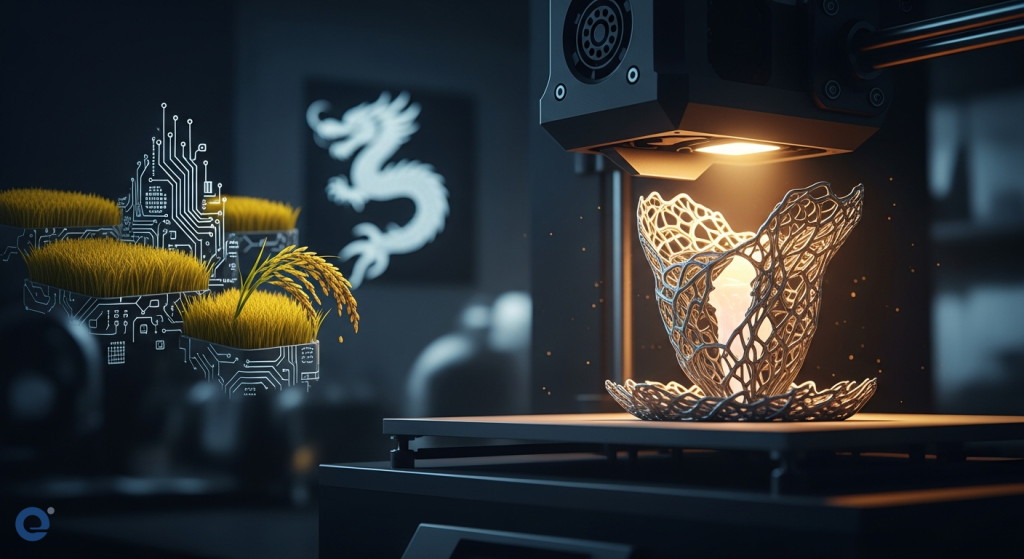

3D printing is a process of creating three-dimensional objects from a digital design. It builds objects layer by layer. This is fundamentally different from traditional subtractive manufacturing methods. These methods remove material from a larger block. Additive manufacturing allows for intricate designs and customization. It also enables the use of a wide range of materials.

The core principle involves a digital model, often created using CAD (Computer-Aided Design) software. This model is then sliced into thin cross-sections. A 3D printer reads these slices and deposits material accordingly. This can be done using various technologies, including fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

Key Advantages of 3D Printing

The advantages of 3D printing are numerous and impactful. Firstly, it allows for rapid prototyping. This means new designs can be tested quickly and efficiently. Secondly, it enables mass customization. Each product can be unique, tailored to specific needs. This is particularly valuable in healthcare. Thirdly, it reduces material waste compared to traditional methods. Finally, it can create complex geometries that are impossible to produce otherwise.

3D Printing in Vietnam’s Biomedical Sector

The biomedical field is a prime area where 3D printing is making significant strides. In Vietnam, this technology holds immense promise for improving healthcare outcomes. It offers solutions for personalized medicine and advanced medical devices.

Customized Implants and Prosthetics

One of the most impactful applications is in creating custom implants and prosthetics. Patients often have unique anatomical structures. Traditional prosthetics may not fit perfectly. 3D printing allows for the creation of devices that perfectly match a patient’s anatomy. This leads to better comfort and functionality. For example, custom bone implants can be designed and printed to fit precisely into bone defects. This is a significant advancement for reconstructive surgery. The use of biocompatible materials is paramount here.

Tissue Engineering and Regenerative Medicine

Tissue engineering is another exciting frontier. Researchers are using 3D printing to create scaffolds for tissue regeneration. These scaffolds can guide cell growth and tissue development. For instance, studies are exploring the use of hydrogels and biocompatible polymers to create structures that mimic natural tissues. These advancements can lead to new treatments for organ damage and disease. The development of bioprinting, which involves printing living cells, is a long-term goal.

Polylactic acid (PLA) is a key material in this area. It is a common aliphatic polyester. PLA is known for its high strength, modulus, biodegradability, and safety profile. Due to its high strength, high modulus, biodegradability, compostability and well-known safety profile, PLA becomes a very useful material for both fundamental researches and practical applications. This makes it ideal for biomedical applications, including scaffolds and drug delivery systems. Researchers in Vietnam are actively investigating its synthesis and properties for these purposes.

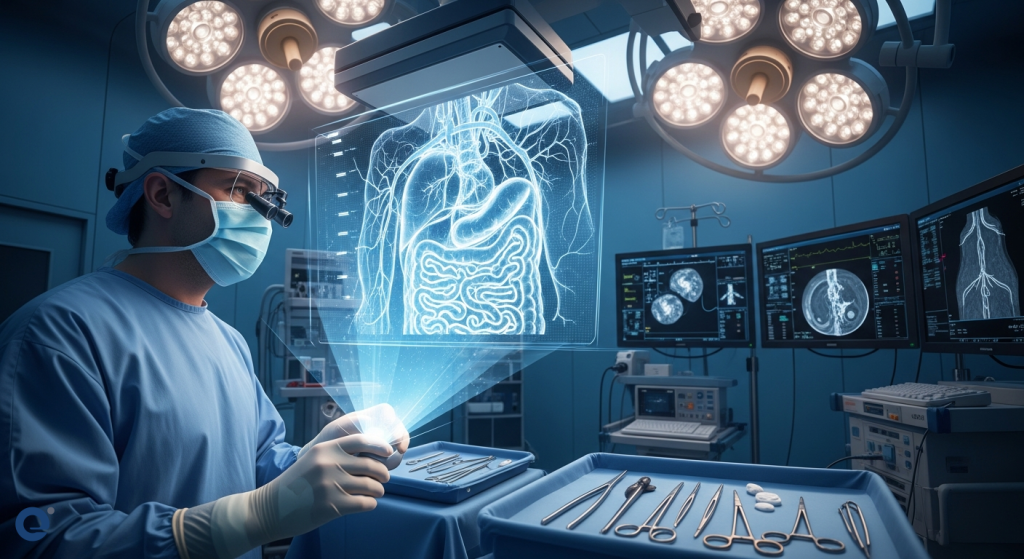

Surgical Planning and Training

3D printing also revolutionizes surgical planning and training. Surgeons can create patient-specific anatomical models. These models allow them to visualize complex procedures before surgery. This reduces operative time and improves patient safety. Furthermore, these models are invaluable for training medical students and residents. They provide realistic simulations of surgical scenarios. This hands-on experience is crucial for developing surgical skills.

3D Printing in Advanced Materials

Beyond biomedicine, 3D printing is a powerful tool for developing and utilizing advanced materials. Vietnam’s growing manufacturing sector can leverage this technology to create innovative products.

Development of Novel Materials

Additive manufacturing facilitates the creation of materials with unique properties. Researchers can experiment with composite materials and multi-material printing. This allows for the development of materials with tailored performance characteristics. For example, printing with different polymers or incorporating nanoparticles can enhance strength, conductivity, or thermal resistance. This opens up possibilities for new applications in aerospace, automotive, and electronics.

Functional Components and Devices

3D printing enables the fabrication of complex functional components. This includes intricate parts that are difficult or impossible to produce with traditional methods. For instance, lightweight yet strong structures for aerospace applications can be designed and printed. Similarly, complex electronic components with integrated functionalities can be developed. This reduces assembly steps and improves overall device performance.

The synthesis and application of materials like PLA are also relevant here. Its properties can be modified for various technical applications. Understanding its physico-chemical properties is essential for successful integration into manufacturing processes. This includes its mechanical, thermal, and electrical characteristics.

Emerging Trends and Vietnam’s Potential

Several emerging trends highlight the growing importance of 3D printing. These trends align well with Vietnam’s development goals and industrial capabilities.

Bioprinting and Organ-on-a-Chip

Bioprinting, the printing of living cells and tissues, is a rapidly advancing field. While still in its early stages, it holds the potential to create functional tissues and even organs for transplantation. Organ-on-a-chip technology, which uses 3D printed microfluidic devices, is also gaining traction. These devices mimic human organ functions for drug testing and disease modeling. Vietnam’s research institutions can play a role in these cutting-edge developments.

Sustainable Materials and Processes

There is a growing emphasis on sustainability in manufacturing. 3D printing offers an advantage by minimizing material waste. Furthermore, research into biodegradable and bio-based printing materials, such as PLA, is crucial. This aligns with global efforts to reduce environmental impact. Vietnam can position itself as a leader in sustainable additive manufacturing practices.

The research output from institutions like TERM-HCMIU showcases a commitment to these advanced fields. Publications such as “Fabrication of 3D printed bi-layered scaffold carboxymethyl chitosan/oxidized xanthan gum, biphasic calcium phosphate for osteochondral regeneration” by My N-H. Nguyen et al. demonstrate concrete steps in this direction. This research highlights the fabrication of 3D printed scaffolds for tissue regeneration, a key area for both biomedicine and advanced materials.

Integration with AI and Automation

The integration of 3D printing with artificial intelligence (AI) and automation is another significant trend. AI can optimize design processes, predict material behavior, and control printing parameters. Automation can streamline production workflows, leading to increased efficiency and scalability. This synergy is essential for unlocking the full potential of additive manufacturing. This is akin to the advancements seen in areas like automated drone delivery, where AI plays a critical role in optimizing operations for remote areas. You can explore this further in our article on Công nghệ Drone: AI và Giao Hàng Tự Động Vùng Xa.

Formlabs Helps Sydney Get a Custom 3D-Printed Prosthesis

Challenges and Opportunities for Vietnam

Despite the immense potential, several challenges need to be addressed for widespread adoption of 3D printing in Vietnam.

Challenges

- Cost of Equipment: High-end 3D printers and materials can be expensive. This can be a barrier for small and medium-sized enterprises (SMEs).

- Skilled Workforce: A skilled workforce is needed to operate and maintain 3D printing equipment. Expertise in design, materials science, and post-processing is also crucial.

- Regulatory Framework: Clear regulations and standards are required, especially for biomedical applications, to ensure safety and efficacy.

- Material Availability: Access to a diverse range of high-quality printing materials, particularly specialized biocompatible ones, can be a challenge.

Opportunities

- Government Support: Government initiatives and funding can accelerate adoption and research in 3D printing.

- Industry-Academia Collaboration: Strong partnerships between universities and industries can foster innovation and technology transfer.

- Local Material Development: Investing in the development of local advanced materials suitable for 3D printing can reduce reliance on imports and create new economic opportunities.

- Niche Market Development: Focusing on specific high-value applications, such as personalized medical devices or specialized industrial components, can provide a strong entry point.

Addressing these challenges proactively will pave the way for Vietnam to become a regional leader in additive manufacturing. The development of advanced materials, like polylactic acid (PLA), is a critical component of this strategy. Understanding its characteristics, properties, and applications in both technical fields and biomedicine is essential for researchers and manufacturers alike.

Frequently Asked Questions (FAQ)

What is the primary advantage of 3D printing for biomedical applications in Vietnam?

The primary advantage is the ability to create highly customized medical devices, implants, and prosthetics tailored to individual patient needs, leading to improved outcomes and patient comfort.

What role does Polylactic Acid (PLA) play in Vietnamese 3D printing for biomedicine?

PLA is a key biocompatible and biodegradable material used for creating scaffolds for tissue engineering, drug delivery systems, and other medical implants due to its favorable safety profile and mechanical properties.

Are there specific Vietnamese research institutions contributing to 3D printing advancements?

Yes, institutions like TERM-HCMIU are actively publishing research in areas such as 3D printed scaffolds for tissue regeneration, demonstrating local expertise and innovation.

What are the main challenges for 3D printing adoption in Vietnam?

The main challenges include the high cost of equipment, the need for a skilled workforce, the development of a supportive regulatory framework, and ensuring the availability of advanced printing materials.

How can Vietnam foster growth in its 3D printing sector?

Fostering growth can be achieved through government support, strong industry-academia collaborations, local material development, and focusing on developing niche market applications.

Conclusion

3D printing, or additive manufacturing, represents a significant technological leap with profound implications for Vietnam’s biomedical and advanced materials sectors. Its ability to enable customization, complex geometries, and efficient prototyping makes it an indispensable tool for innovation. As Vietnam continues to invest in research and development, and foster collaborations between academia and industry, the potential for 3D printing to drive economic growth and improve quality of life is immense.

By understanding and strategically implementing this technology, Vietnam can position itself at the forefront of advanced manufacturing. This will not only enhance its healthcare system but also bolster its capabilities in producing high-value materials and components for various industries. The journey requires overcoming challenges, but the opportunities are undeniably vast.